Engine Rebuiling-Performance Engine Rebuilding-Automotive Machine Shop

Performance Automotive ® 475 S Prairie St, Bethalto, IL 62010 (618) - 377-0027.................. Site Designed By AMS Web Designs 1-413-566-0037

CNC Lifter Bore Correction

Lifter Bore Repair Lifter Bore Sleeve

CNC Lifter Bore Correction , Sleeving and Blueprint:

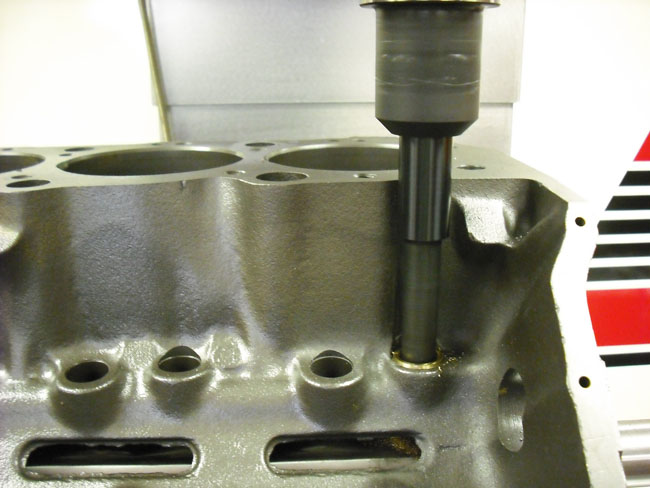

Probing Routine.The CNC Probing Routing Verifies the lifter bores to the exact diameter, blueprint location and angle so corrections can be made to their position in an engine block front-to-rear and up-and-down, as well as to restore the correct lifter bore angle as referenced from the cam-crank centerline .

CNC Lifter Bore Correction ,Sleeving and Blueprint and Repair:

Machine lifter bores to the exact diameter, location and angle. True up the stock size and location or bore complete new diameter, location or angle. The Rottler F69A CNC Machine enables Performance Automotive to re-machine the lifter bores and correct their position in an engine block front-to-rear and up-and-down, as well as to restore the correct lifter bore angle as referenced from the cam-crank centerline. Rottler F69A CNC Engine Block Blueprinting machine utilizes the Renshaw Probe with the lifter blueprinting program to positions the precise blueprinted lifter bore location and angle.

Rottler F69A PC based with Windows Operating System

Dimensions input thru touch screen:

Bore centers, exact depth, speed, feed, etc.

Bores complete bank in Automatic Cycle. (Precision blueprint fixture)

Bores both banks in automatic cycle (4 Th axis rotary fixture)

Lower Bore Relief, off center boring for Honing Clearance.

Surfacing - Multiple Pass programmable for roughing and finishing - can remove any amount of material in one automatic cycle.

Lifter bore machining - bore housings and ream bushes to exact final size.

Automatic line bore cycle completes all main bearing housings to within .0002".

Machine a radius for stroker crank connecting rod and bolt clearance.

Rottler CAM CNC program allows G code programming and file transfer with CAD/CAM programs.

Windows 7 Touch Screen Control.

The Rottler F69A is a true simultaneous 4 axis Windows XP based rigid spindle CNC Bed Mill. The available 360 degree 4th -axis block system allows automatic block positioning for many machining operations. Our digital probing system is an automated coordinate measuring device.

CNC Lifter Bore Correction Lifter Bore Repair Lifter Bore Sleeve

BHJ's Lifter Bore Sleeves are available in both SAE 660 Bronze and A-48 Cast Iron in a variety of sizes to suit standard Chevrolet, Ford and Chrysler I.D. applications. Standard Lifter Bore Sleeve (Lifter Bushing) sizes are nominal 1" O.D., by 1.500" long and are of a standard "Barrel Bushing" design.

All Sleeves are made-to-order and sized per the application. Press-fit O.D. sizes are dependent upon the size lifter being used, as well as the hole in the block into which the Sleeves will be installed. This hole-size must be specified when ordering to ensure proper press fit during installation. Longer Sleeve lengths are also available for applications with tall lifter bosses or other performance applications. Lengths of 1.600" through 2.00" are available for most I.D./O.D. combinations and must be specified when ordering. Shouldered, or other custom Sleeve design configurations can be accommodated on a special order basis.

Bronze Sleeves are also available in .937" I.D. for Jesel and other aftermarket lifter applications. Standard 1" O.D. as well as special 1.062" O.D. are also available for all I.D. sizes, though it is typically recommended that .937" Bushings use the 1.062" O.D. to maintain greater wall thickness. Cast iron Sleeves are available in longer lengths and special configurations mentioned above, but are not available in .937" I.D. or 1.062" O.D.